Comprehensive Guide to Plastic Injection Molding and Machining Services

October 9, 2024 | by yanglin_mold@163.com

Understanding Plastic Injection Molding and Die Casting

Plastic injection molding and die casting are two prevalent manufacturing processes used to produce intricate parts and components across various industries. Each of these techniques offers unique advantages, and understanding their fundamental concepts is essential for selecting the most suitable method for specific applications.

Plastic injection molding involves the heating and melting of plastic materials, which are then injected into a mold under high pressure. Once the material cools and solidifies, it takes the shape of the mold, resulting in a finished product. This process is renowned for its efficiency and capability to produce complex geometries with precise dimensions. Typical products created through injection molding include consumer goods, automotive parts, and medical devices.

On the other hand, die casting is primarily used for producing metal parts, where molten metal is poured into a mold made of steel or iron. This technique enables manufacturers to achieve high dimensional accuracy, superior surface finish, and reduced need for post-processing. Common materials utilized in die casting include aluminum, zinc, and magnesium, often resulting in products such as engine components and structural parts.

Selecting the appropriate materials, tooling, and technology is crucial for achieving high-quality results in both processes. For instance, using the right thermoplastics or alloys can significantly impact the durability and performance of the final component. Moreover, attention to detail during the design of molds and tooling can mitigate common challenges, such as warping or incomplete filling. Best practices might include conducting thorough tests and simulations to optimize designs before production begins.

Both plastic injection molding and die casting offer invaluable benefits, including cost-effectiveness and scalability, making them essential methods in modern manufacturing. By gaining a deep understanding of these processes, manufacturers can leverage their capabilities for a wide range of applications.

From Design to Delivery: Our All-in-One Service Approach

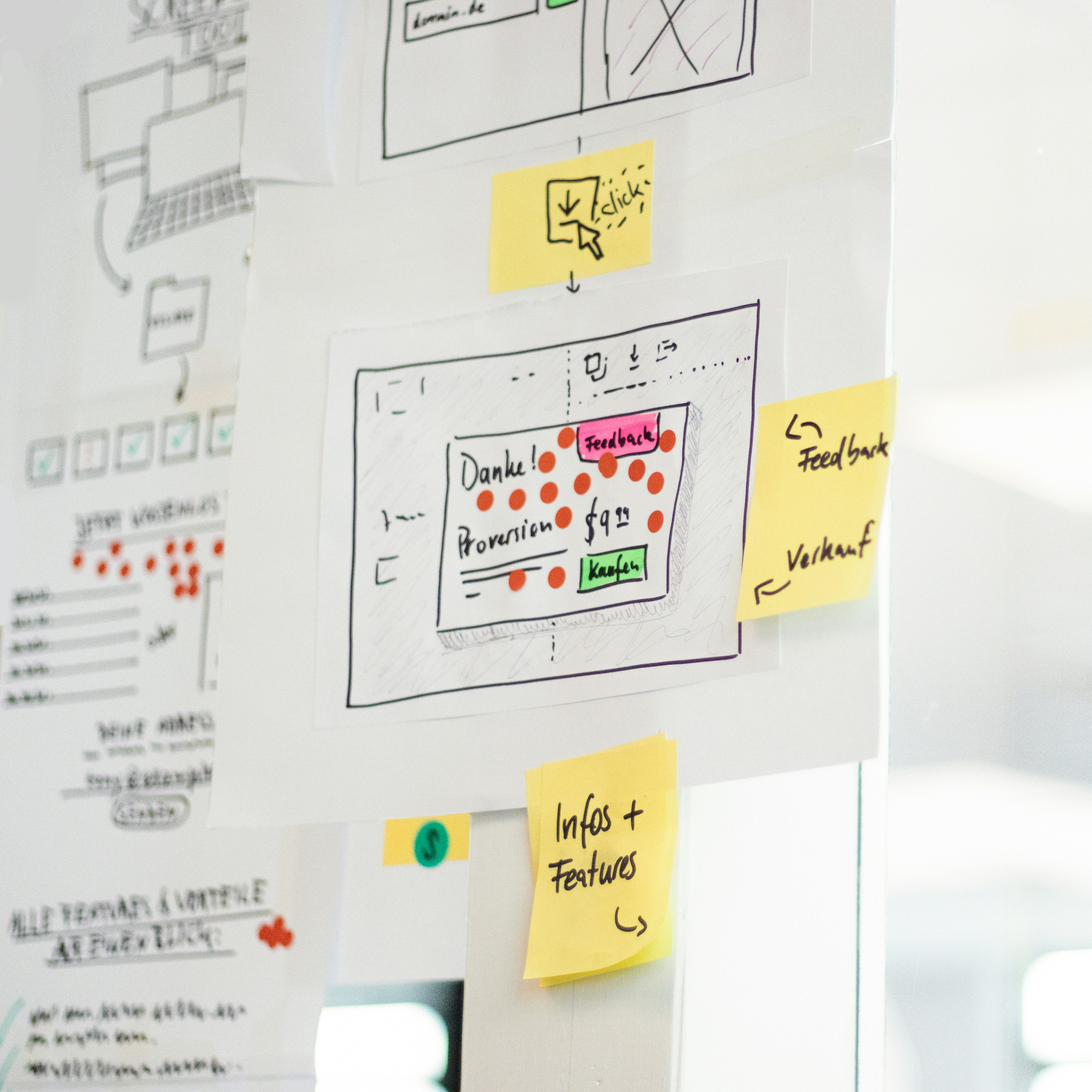

The journey of product development through our all-in-one service approach begins with innovative product design. This initial stage is paramount, as it lays the foundation for the entire manufacturing process. Our team collaborates closely with clients to ensure that each design meets functional requirements while considering aesthetic appeal. This collaboration often involves creating 3D models and simulations to visualize the end product effectively.

Following the design phase, we progress to prototyping, where tangible models are developed to evaluate functionality, design integrity, and manufacturability. Utilizing advanced technologies, such as computer-aided design (CAD) and rapid prototyping techniques, we produce high-quality prototypes that mimic the actual product. This stage is crucial, as it allows for rigorous testing and the identification of potential issues before full-scale production begins.

Testing plays a central role in our comprehensive approach, ensuring that prototypes meet all specified requirements and industry standards. We conduct various tests, including mechanical, thermal, and electrical assessments, to validate performance and durability. Additionally, our strict adherence to certification processes guarantees that all products comply with relevant regulations, providing clients with peace of mind regarding safety and quality.

Once the product design is finalized and passed testing, we move on to assembly, packing, and delivery logistics. Our integrated services ensure that products are assembled efficiently, packed securely, and delivered to clients in a timely manner. By streamlining the manufacturing process, we not only save time but also reduce costs, ultimately providing our customers with cost-effective solutions without compromising on quality.

This all-encompassing service approach reflects our commitment to excellence and customer satisfaction, guiding each project from its inception to flawless execution.

RELATED POSTS

View all